Comparison between traditional extraction and supercritical carbon dioxide extraction

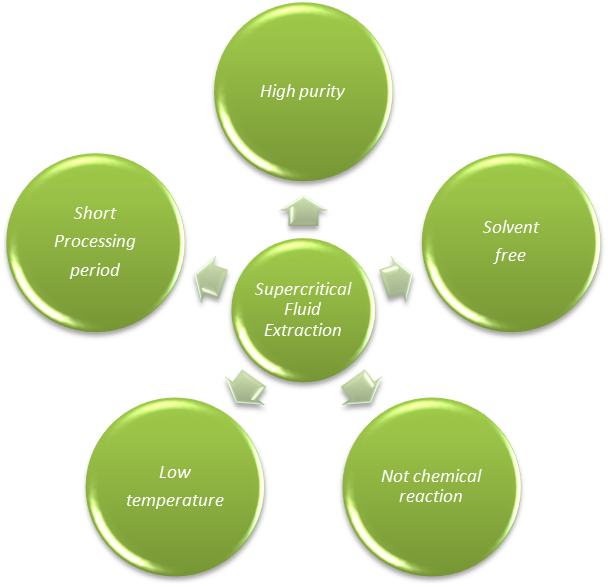

Landlord:17600603718 time:12-12 10:24 Click:978 Reply:0 CollectionTechnical advantages of Supercritical Fluid Extraction

high purity

No chemical reaction

Short processing time

Low temperature extraction

No solvent

Supercritical carbon dioxide extraction:

The supercritical carbon dioxide fluid is extracted at a low temperature slightly above room temperature (31 ° C) without changing or destroying the components susceptible to heat; suitable for the separation of heat sensitive substances.

It is colorless, odorless, non-toxic, non-residue, environmentally friendly, gas under normal pressure, does not leave odor and destroys the product, and is easy to separate from the product, retaining the most original flavor of the substance.

Carbon dioxide is chemically inert, oxygen-free, and does not chemically act; it does not alter or destroy the active ingredients in the extract. And the supercritical extraction process is closed, so the product extracted by supercritical carbon dioxide fluid can extend the shelf life.

The optimum solubility of each component can be obtained by adjusting the extraction temperature and pressure; or a high purity extract can be obtained by adding a modifier and using high purity carbon dioxide.

In the conventional solvent extraction process of a general factory, if an organic solvent is added, not only the extraction time is long, but also the environmental ecology and cost are seriously affected. In addition, since the organic solvent has an oxidation effect, by-products such as water may be generated, but carbon dioxide is not oxidized. Role and the above adverse effects.

Distillation method: Although the distillation method can extract most of the essential oils, since the essential oil itself has heat sensitivity, the produced essential oil will deteriorate due to high temperature, and the original components of the substance cannot be retained. The process is lengthy and requires high temperatures to remove moisture.

Pressing method: The pressing method is very easy to destroy the original structure of the raw material, thereby affecting the quality of the product and causing the occurrence of unintended products, which easily deteriorates the product. Short process and low cost are its advantages.

Organic solvent extraction method: The organic solvent extraction method is not time-consuming and low-cost, and is highly favored by the perfume and essential oil industries. However, the organic solvent is not easily separated after extraction, and the chloroform or phenyl solvent is carcinogenic.

Technical advantages of Supercritical Fluid Extraction

high purity

No chemical reaction

Short processing time

Low temperature extraction

No solvent

Comparison between traditional extraction and supercritical carbon dioxide extraction

Supercritical carbon dioxide extraction:

The supercritical carbon dioxide fluid is extracted at a low temperature slightly above room temperature (31 ° C) without changing or destroying the components susceptible to heat; suitable for the separation of heat sensitive substances.

It is colorless, odorless, non-toxic, non-residue, environmentally friendly, gas under normal pressure, does not leave odor and destroys the product, and is easy to separate from the product, retaining the most original flavor of the substance.

Carbon dioxide is chemically inert, oxygen-free, and does not chemically act; it does not alter or destroy the active ingredients in the extract. And the supercritical extraction process is closed, so the product extracted by supercritical carbon dioxide fluid can extend the shelf life.

The optimum solubility of each component can be obtained by adjusting the extraction temperature and pressure; or a high purity extract can be obtained by adding a modifier and using high purity carbon dioxide.

In the conventional solvent extraction process of a general factory, if an organic solvent is added, not only the extraction time is long, but also the environmental ecology and cost are seriously affected. In addition, since the organic solvent has an oxidation effect, by-products such as water may be generated, but carbon dioxide is not oxidized. Role and the above adverse effects.

Distillation method: Although the distillation method can extract most of the essential oils, since the essential oil itself has heat sensitivity, the produced essential oil will deteriorate due to high temperature, and the original components of the substance cannot be retained. The process is lengthy and requires high temperatures to remove moisture.

Pressing method: The pressing method is very easy to destroy the original structure of the raw material, thereby affecting the quality of the product and causing the occurrence of unintended products, which easily deteriorates the product. Short process and low cost are its advantages.

Organic solvent extraction method: The organic solvent extraction method is not time-consuming and low-cost, and is highly favored by the perfume and essential oil industries. However, the organic solvent is not easily separated after extraction, and the chloroform or phenyl solvent is carcinogenic.